I'm thrilled to share valuable insights that will aid both novices and professionals in the concrete industry. Today, we'll explore the paramount importance of admixture-cement compatibility and its significant impact on concrete performance.

- The Significance of Admixture-Cement Compatibility

- Effects of Incompatibility on Concrete Performance

- Ensuring Compatibility for Concrete Excellence

The Significance of Admixture-Cement Compatibility:

In the daily work of concrete professionals, the compatibility between admixtures and cement cannot be overstated. Admixtures play a pivotal role in modifying concrete properties, enhancing workability, improving durability, and tailoring performance to meet specific project requirements. However, using incompatible admixtures with cement can lead to various issues that compromise the integrity and longevity of the concrete.

Effects of Incompatibility on Concrete Performance:

When admixtures and cement are not harmonious, undesirable consequences arise. For instance:

a. Reduced Strength: Incompatible admixtures can hinder cement hydration, resulting in decreased concrete strength and diminished load-bearing capacity.

b. Altered Setting Time: The setting time of concrete can be adversely affected, causing delays in construction or challenging handling and placement.

c. Slump difference is low: Incompatibility may lead to poor workability and slump, making it difficult to achieve the desired finish.

d. Increased Permeability: Incompatible admixtures can raise concrete permeability, rendering it susceptible to water ingress and deterioration.

e. Durability Concerns: Unfavorable reactions can impact concrete durability, leaving it vulnerable to environmental factors like freeze-thaw cycles and chemical attacks.

f. Segregation and Bleeding: Incompatibility may cause segregation and excessive bleeding, leading to poor surface quality and reduced strength.

Ensuring Compatibility for Concrete Excellence:

To produce top-notch concrete with optimal performance, adhering to the following guidelines is essential:

a. Use Reputable Admixtures: Choose high-quality admixtures from trusted manufacturers that comply with industry standards.

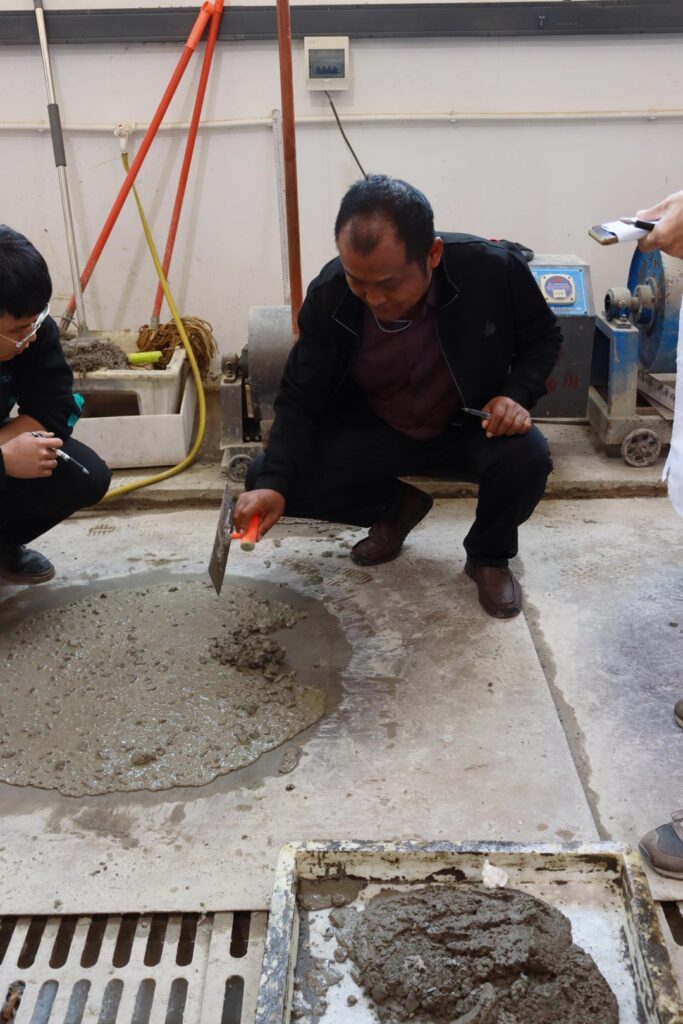

b. Conduct Compatibility Tests: Before large-scale production, perform compatibility tests between chosen cement and admixture combinations to identify any potential issues.

c. Follow Manufacturer Recommendations: Adhere strictly to recommended dosages and mixing procedures to prevent over- or under-dosing.

d. Trial Mixes for Optimization: Experiment with different proportions of admixtures and cement in trial mixes to achieve the desired concrete properties.

e. Monitor Concrete Performance: Regularly test hardened concrete for strength, durability, and relevant properties to ensure it meets project requirements.

In conclusion,The compatibility of cement and admixtures is a very meaningful scientific problem, and it is also a practical engineering problem. This problem arises from an engineering accident. Therefore, the production unit and the engineering application department must pay great attention to it.Remember that attention to detail and expertise in admixture-cement interactions can lead to concrete excellence in all your projects.