Concrete admixtures are materials added before or during the mixing of concrete. Their main purpose is to improve the properties of fresh or hardened concrete. Construction requirements keep increasing, demanding various properties from concrete, such as high fluidity, early strength, high strength, quick setting, slow setting, frost resistance, permeability resistance, and low heat of hydration.

Concrete admixtures are chemical substances that can enhance the performance of concrete. They come in many varieties. Choosing the right concrete admixture is crucial to ensuring concrete quality. This article will introduce some common types of concrete admixtures.

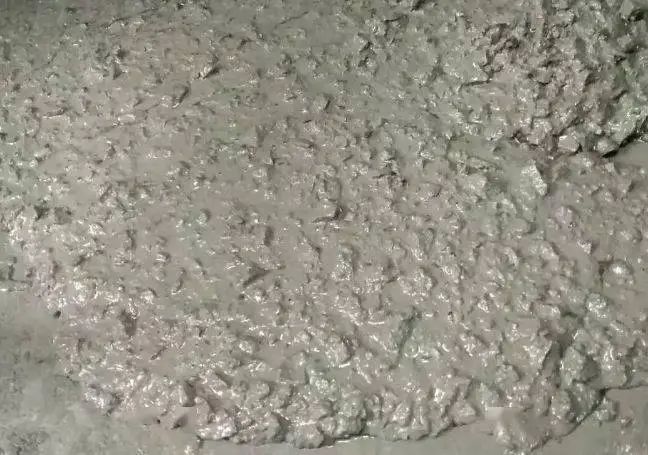

Water Reducer

A water reducer is an admixture that reduces the amount of mixing water while maintaining a consistent slump in concrete. It disperses cement particles in the mixture, improving workability and reducing the water-to-cement ratio. This also enhances the flowability of the concrete mix and reduces cement usage, thus saving material costs. Additionally, it significantly improves the durability of the concrete.

Early Strength Agent

The early strength agent, also known as an accelerator, increases the early strength of concrete without significantly affecting later strength. Its primary function is to accelerate the hydration rate of cement, promoting early strength development. Early strength agents are among the earliest types of admixtures used in construction. They have played a vital role in improving concrete performance, enhancing construction efficiency, and reducing investment costs.

Retarder

Concrete retarders extend the hydration of cement and delay setting time. They allow fresh concrete to remain workable for longer periods. Retarders counteract the rapid setting of concrete under high temperatures and do not adversely affect the later strength of the concrete. They are suitable for continuous pouring in hot conditions, large volume concrete, ready-mixed concrete, and pumped concrete.

Expanding Agent

An expanding agent is a new type of concrete admixture that reacts with water and cement to produce crystalline structures that increase in volume. When cement sets, this expansion creates pre-stress, compensating for shrinkage and providing pre-stressing for reinforcement while filling gaps in the cement.

Air-Entraining Agent

An air-entraining agent is a type of anionic surfactant. It incorporates micro-bubbles of air into the concrete mix during mixing, distributing them evenly throughout the structure. These micro-bubbles remain stable over time. The agent dissolves in water and can be adsorbed at gas-liquid interfaces, helping to stabilize bubbles and prevent rupture. Increasing the dosage of air-entraining agents raises the air content in concrete. This admixture is suitable for use in ports, docks, hydraulic projects, road surfaces, and other applications requiring specific air content.

Quick Setting Agent

A quick setting agent is essential for shotcrete applications. It causes the cement to set rapidly. The agent interacts with cement minerals to form stable, insoluble compounds, speeding up the formation of the matrix. Their purpose is to accelerate hydration and achieve sufficient strength in a short time, meeting special construction demands. This additive is typically used in shotcrete applications.

Pumping Agent

A pumping agent improves the pumpability of concrete. This term refers to the ability of the concrete mix to pass smoothly through delivery pipes without blockage, segregation, and with good plasticity. Pumping agents often consist of a blend of water reducers, retarders, air-entraining agents, and anti-blocking agents. They enhance flow, cohesion, lubrication, and retardation, making them suitable for producing high-strength or fluid concrete.

Currently, the most commonly used admixtures are water reducers. Widely used types include naphthalene-based and polycarboxylate-based water reducers. Water reducers act as surfactants, allowing reduced water usage while maintaining the same flow, improving concrete strength and durability. High-performance concrete relies on efficient water reducers.