Polycarboxylate Monomer EPEG/GPEG

Vinyl diethylene glycol polyoxyethylene ether,EPEG/GPEG

Download Product Date Sheet

Download Product Date Sheet

Product Description

EPEG/GPEG/C6 Monomer is the latest main raw material for the production of polycarboxylic acid superplasticizer, which is prepared by the reaction of vinyl diethylene glycol and ethylene oxide. In the production process of PCE, it is generally used to produce water-reducing type, comprehensive type, slow release type and slump retaining type water reducer. As long as we master the production and use technology of C6 monomer, we can produce a full range of water reducing agents with better effects than HPEG/TPEG. Polycarboxylate superplasticizer can be produced by free radical polymerization by refrigeration method or oxidation-reduction method at room temperature.

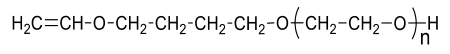

Product Molecular Structure

EPEG Molecular structure:

Technology Service

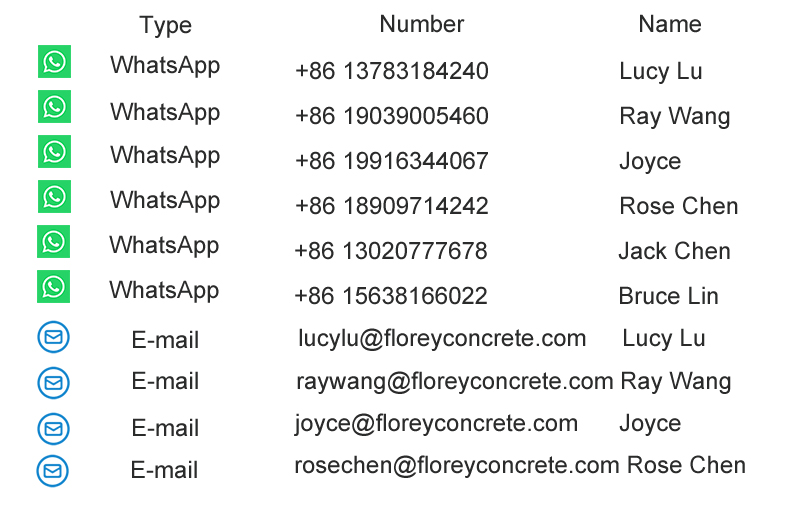

If you need to use EPEG/GPEG/C6 Monomer to produce PCE water-reducing type, comprehensive type, slow release type and slump retaining type, please contact our company, our company can provide a full set of production technology and process formula.

PCE production synthesis technology, concrete technology, concrete admixture technology

Welcome consultation:

Application

Polycarboxylate ether monomer EPEG is the main raw material for producing polycarboxylate water reducing agents.

EPEG is a highly efficient polycarboxylate water reducing agent copolymerized with acrylic acid, which has excellent slump retention and good adaptability. The synthesized PCE has good dispersibility and slump retention, strong adaptability, and good viscosity reduction effect. Especially suitable for projects with poor sand and gravel quality, high sand content, or high requirements for concrete.