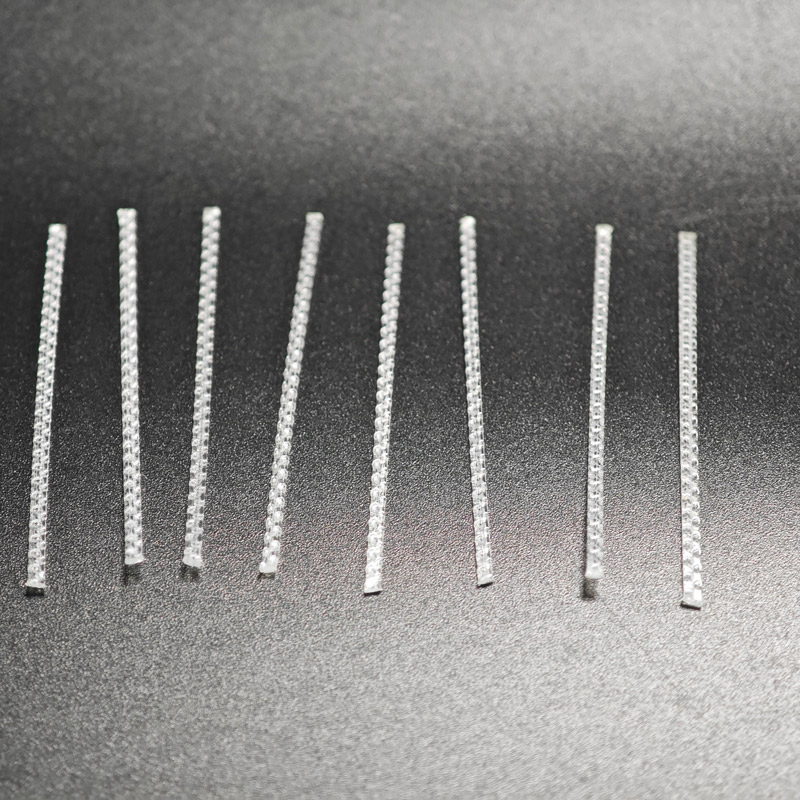

polypropylene crude fiber

polypropylene crude fiber for Concrete Reinforcement

Product Description

Polypropylene crude fiber uses synthetic fibers as raw materials. Through special processes and surface treatments, it offers high breaking strength, excellent dispersion in concrete, and strong bonding force. Replacing steel fibers in cement concrete, it addresses the material's low tensile strength, limited ultimate elongation, and brittleness.

The fiber provides tensile resistance, shear resistance, crack prevention, fatigue resistance, and high toughness. It has been widely used in construction, roads and bridges, hydraulic engineering, and other fields.

Product features

Inhibits and controls the formation of intrinsic cracking in concrete

Increases cohesion and reduces segregation

Reduces settlement and bleeding

Reduces plastic shrinkage and settlement cracking

Increases impact and shatter resistance

Reinforces against abrasion

Reduces freeze/thaw damage

Provides durability

Alternative system to traditional reinforcement when used for secondary (crack control) reinforcing in concrete

Application

(1). Suit for the waterproof layer, floor, inner & outer wall of industrial and civil construction.

(2). Increase cracking resistance on the surface of industrial workshop, warehouse and parking lot.

(3). Increase cracking & seepage resistance of the ground in natatorium, swimming pool, pond and ditch.

(4). Suit for any mortar projects and common concrete projects.

(5). Highway, bridge and other roads.

(6). Prevent shrinkage in ready-mix concrete and precast concrete.

(7). Fire-resistant concrete structure.

(8). Precast concrete segments for final lining of tunnels.

Prefabricated buildings and components

Prefabricated buildings and components

Prefabricated buildings and components

Package & Storage

1kg net per PE bag, 20kgs per plastic woven bag.

Store in cool and dry environment, keep away from sunlight.

The shelf life is2 year( 24 months)

Product specification

| Fiber type | Bunched monofilament | Density | 0.91±0.01 |

| Diameter | 20-50um(micron) | Tensile strength | ≥350Mpa |

| Resistance to ph | very high | Melting point | 160-170℃ |

| Thermal conduction

|

very low | Water absorption | No |

| Elasticity modulus | 〉3500MPa | Length | 3mm-30mm |

| Safety performance | Green environmental protection, non-toxic | Dispersibility | Good |