Product Description

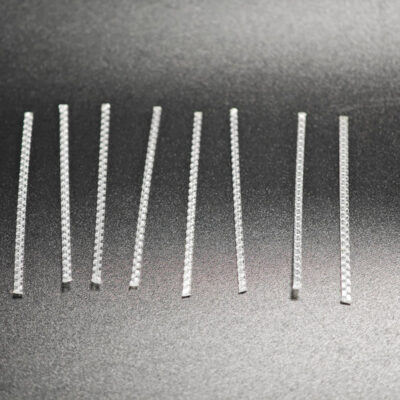

Twisted bundle fiber (abbreviated as: twisted fiber) enhance polypropylene fiber. These high-performance fiber apply to construction projects. Twisted fiber resist acid and alkaline corrosion. It have high tensile strength and large elastic modulus. It also show strong resistance to acids and bases. Polypropylene fiber disperse easily and are simple to install. It do not damage mixing equipment.

The twisted bundle reinforced polypropylene fiber use polypropylene as the raw material. A special processing method, drawing, and surface treatment create these fibers. They feature high breaking strength, good dispersion in concrete, and strong bonding capability. These fibers widely enhance cement concrete by improving crack resistance, impermeability, and aging resistance.

Application

Improves the crack resistance of concrete.

Enhances the impermeability of concrete.

Boosts the wear resistance of concrete.

Increases the impact and fatigue resistance of concrete.

Strengthens the bending and flexural performance of concrete.

Improves the internal reinforcement protection of concrete.

Enhances the plastic deformation ability of concrete, especially high-strength concrete.

Offers strong acid and alkaline resistance, ensuring excellent durability.

Prefabricated buildings and components

Prefabricated buildings and components

Prefabricated buildings and components

Package & Storage

1kg net per PE bag, 20kgs per plastic woven bag.

Store in cool and dry environment, keep away from sunlight.

The shelf life is2 year( 24 months)

Technology Service

- Dosage:

For high crack resistance requirements, add no less than 2.6 kg of twisted fiber per cubic meter of concrete.

For standard crack resistance requirements, use 0.7 kg - 0.9 kg of twisted fiber mixed with 0.4 kg - 0.6 kg of mesh fiber per cubic meter of concrete for better results. - Mixing Procedure:

First, add stones and fibers, then add sand and cement materials for mixing. Alternatively, you can mix the fibers directly with sand and gravel. Extend the mixing time appropriately to ensure complete dispersion of the fibers. - Packaging:

Packaged in woven bags, 10 kg per bag (customizable based on customer requirements).

Product specification

| Fiber type | Twisted Fiber | Density | 0.91-0.98 |

| Diameter | 0.1-0.3(mm) | Tensile strength | ≥500Mpa |

| Resistance to PH | Very high | Melting point | 160-170℃ |

| Thermal conduction | Very low | Water absorption | No |

| Elasticity modulus | 〉3500MPa | Length | 40-50 mm |

| Safety performance | Green environmental protection, non-toxic | Acid and Alkali Resistance | Good |